Molybdenum Disilicide Heating Elements

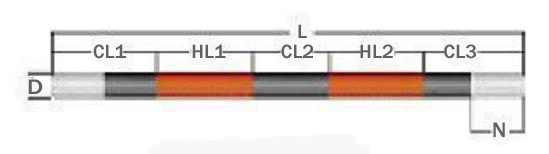

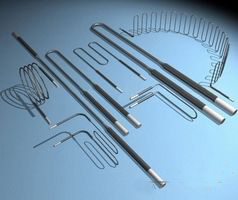

molybdenum disilicide MoSi2 heating elements are for element temperatures up to 1850°C. MoSi2 heating elements are available as straight or bent elements in a wide range of shapes and sizes, all characterized by long life and consistent performance.

Seven grades for different applications

The program of MoSi2 heating elements includes seven grades with specific features for use in demanding applications and atmospheres, including nitrogen, hydrogen, vacuum and mixtures of endogas and reducing atmospheres.

All MoSi2 heating elements are characterized by good heat and electrical conductivity. They have low thermal expansion and withstand corrosion and oxidation.

Special design

In addition to MoSi2 elements in standard shapes and sizes we provide special designed MoSi2 elements according to customer needs, enabling an optimized element design for each particular application

MoSi2 heating elements are available as straight or bent elements in a wide range of sizes and shapes.

MS1700 — Good heat and electrical conductivity. Low thermal expansion. Withstand corrosion and oxidation. Max. temperature is 1700°C

MS1800 — Same core characteristics as MS 1700. Max. temperature is 1800°C

MS1900 — Same core characteristics as MS 1700, but has higher purity and a surface with better adhesion. Max. temperature is 1850°C

Useful element temperatures in various atmospheres, ºC

| Grade | 1700 | 1800 | 1900 |

| Air | 1700 | 1800 | 1850 |

| Nitrogen | 1600 | 1700 | 1800 |

| Argon, Helium | 1600 | 1700 | 1800 |

| Hydrogen

Temperature is dependent on dew point. |

1100-1450 | 1100-1450 | 1100-1450 |

| Nitrogen/Hydrogen 95/5% | 1250-1600 | 1250-1600 | 1250-1600 |

| Exogas (e.g. 10% CO², 5% CO, 15% H²) |

1600 | 1700 | 1700 |

| Endogas (e.g. 40% H², 20% CO) |

1400 | 1450 | 1450 |

| Cracked and partially burnt ammonia (~8%H² ) | 1400 | 1450 | 1400 |