Molybdenum Disilicide Heating Elements

MoSi2 Heater Molybdenum Disilicide Heating Elements

Quality product – Great price- Exceptional support

MoSi2 heater Molybdenum disilicide heating elements are resistance type heating elements made of a dense ceramic-metallic material which can produce furnace temperatures approaching 1800°C. Although more expensive than traditional metallic elements, MoSi2 heating elements are known for their longevity due in part to a protective quartz layer that forms on the surface of the element “hot zone” during operation.

MoSi2 heater Molybdenum disilicide heating elements are made to industry standard established resistance values, dimensions and geometries, and therefore are interchangeable with other manufacturers of molybdenum disilicide heating elements. The key difference between MoSi2 and other MoSi2 suppliers is that MoSi2 heating elements are exceptionally priced.

MoSi2 heater Molybdenum disilicide heating elements are graded in two maximum temperature ranges of 1700°C (3090°F) and 1800°C (3270°F). Elements are available in many shapes and forms (see examples shown below). Specifically, we offer the following MoSi2 styles: “U-shaped” (most common), “W-shaped”, and “Straight-shaped”, with or without right angle or oblique angle bends.

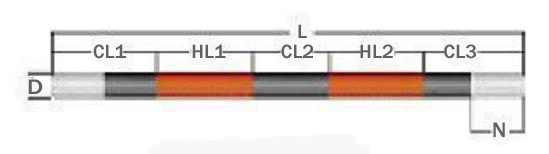

Each MoSi2 heater is specified by a “hot zone” diameter (de) and length (Le), and a “cold zone” diameter (du) and length (Lu).

Examples of typical MoSi2 heating elements configurations.

| 3/6mm | Le=Ф3mm | Lu=Ф6mm | L=25-30mm |

| 4/9mm | Le=Ф4mm | Lu=Ф9mm | L=25-30mm |

| 6/12mm | Le=Ф6mm | Lu=Ф12mm | L=30-50mm |

| 7/14mm | Le=Ф7mm | Lu=Ф14mm | L=30-50mm |

| 9/18mm | Le=Ф9mm | Lu=Ф18mm | L=35-60mm |

| 12/24mm | Le=Ф12mm | Lu=Ф24mm | L=60-100mm |

Benefits of MoSi2 heating elements include high temperature operation (in air), long element life and the ability in some cases to replace any failed elements hot.

Customers of MoSi2 heating elements enjoy two key all benefits – first, unparalleled price and second, experienced engineering support. Anyone can sell MoSi2 heater, but knowing how to design the system is where excels. MoSi2 systems must be engineer for customer to get the best performance and optimum service life. engineers can assist in:

analyzing the relationship between the furnace temperature, element temperature and the element surface load

selecting the element surface local according to the furnace construction, atmosphere and operating temperature

choosing the most suitable MoSi2 heater size and style for your application